Tests and activities of the Laboratory

A test that measures the resistance to the deformation of the bolt holes of the steel wheel.

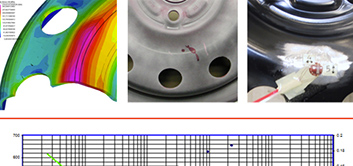

A test to verify the corrosion resistance of the surface-treated wheel subjected to extreme conditions.

A resilience test to evaluate the resistance of alloy wheels subject to impact through a collision simulation.

Press able to measure force, pressure and displacement of the actuator.

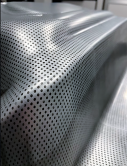

Non-destructive tests by means of liquid penetrant inspection to assess materials defects with no product damage.

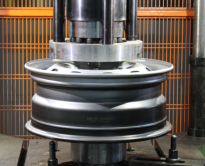

A test for steel wheels for the evaluation of rim deformation by simulating a frontal contact with obstacles.

A fatigue test that allows to evaluate the wheel resistance during rolling under load, as on a road drive.

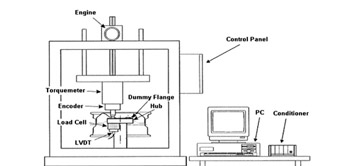

A fatigue test with rotating bending moment that simulates the load condition to which the wheel is subject to when in use.

Test e valutazione della resistenza del rivestimento superficiale alla scheggiatura dovuta all’impatto con la ghiaia.

A test to evaluate the harmonic response of the wheel, recording generated frequencies and vibration modes, and how this influences the dynamic behaviour of the vehicle.

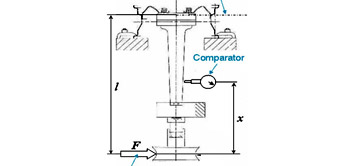

A test to measure the static stiffness of the wheel.

A test for the detection of the deformation inside the wheel under load.

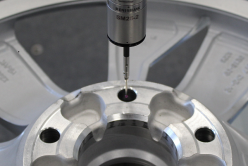

3D coordinate-measuring machine for single measures in manual or automatic mode, profiles and surface scans.

A machine to record profiles by means of a touch-probe for the 2-dimensional comparison of real profiles with theoretical ones.

A road simulator that applies radial and lateral loads with dynamic variations during the test to evaluate the wheel fatigue resistance.

The dynamometric wheel is mounted to measure the loads and forces the wheel is subjected when operating.

The test allows the shifting fork to be fatigue tested according to the FPW.MTD016 standard, applying an alternating uniaxial load to the snug.

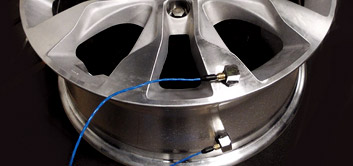

A test that evaluates the surface stress of a component subjected to a load by measuring the material surface strain.

Metal structure analysis

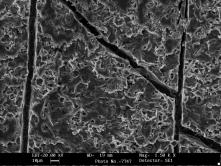

The SEM (Scanning Electron Microscope) is a very useful tool in micro and nano-structural investigation. It allows the study of high magnification of surfaces (fractures, topography).

The material to be analyzed is subjected to a powerful electrical discharge. Under the effect of this discharge, part of the surface vaporizes creating a cloud of excited ions that emit electromagnetic radiation.

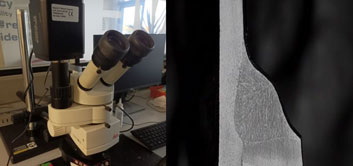

The macroscopic analysis of welded joints on metallic materials allows to verify the shape and quality of the welds

In a tensile test the specimen, usually a dog bone, is deformed by gradually increasing the axial load until failure.

Ideal system for the testing of components and materials such as plastics, elastomers, aluminum, composites, steel, super alloys and more.

The Vickers microdurometer is used to perform high precision hardness tests (hardened surface layers, surface coatings of small parts, inclusions, second phases ...).

Optical forming analysis

Homologation package according to specifications