Non-destructive testing (NDT) is so defined as to assess the defects of materials without damaging, destroying or altering in whatsoever way the physical state and the geometric configuration of the products being tested.

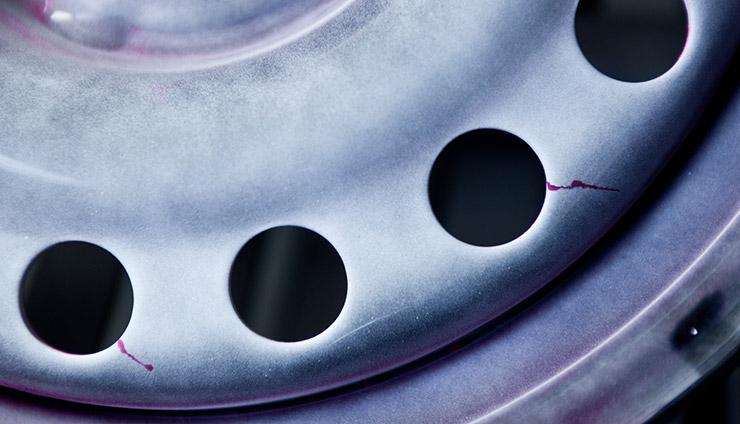

In particular, the working principle of LPI (liquid penetrant inspection) operations is based on a low-tension liquid substance and with high wetting power capable of penetrating into very fine surface discontinuities.

The surface defects absorb the liquid by capillarity and not by gravity, such main characteristic, which is the basis of all testing methods, makes it easy to check surfaces difficult to access regardless of their position.

A second substance (detector) highlights the capillary rise, forming visual indications to the naked eye at the same level of the defect.

The indications obtained must be observed and evaluated under white light.

Users

Wheels manufacturers

Cars manufacturers

Light commercial vehicles manufacturers

Steel components stamping and rollforming industry

The test fulfills the requirements of the majority of automobile and light commercial vehicle manufacturers.

Personnel with qualification: PT license for Level 2 (UNI EN ISO 9712).