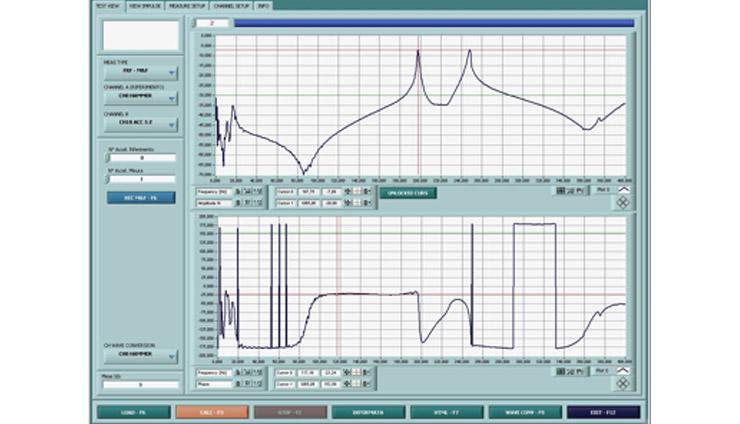

The harmonic response of the wheel is evaluated by means of the impact hammer test.

This test employs an impulse due to a hammer impact and the generated resonance frequencies and modes of vibration are recorded through accelerometers.

Indirect information about the stiffness of the component can be obtained and employed to evaluate their influence on the dynamic behaviour of the vehicle.

Users

Wheels manufacturers

Cars manufacturers

Light commercial vehicles manufacturers

Instruments / Test Machines

The system “Noise & Vibration Analyzer” is able to record parameters related to the dynamic behaviour of the wheel and the vehicle.

The system is composed of:

3 data acquisition card for a total of 24 channels;

8 tri-axial accelerometer;

1 hammer with different impact head (to generate the impulse impact on the object);

1 PC for data acquisition and post-processing;

cables and connectors;

1 software designed for the dynamical analysis (implemented in the LABVIEW environment).

Standard references

The test fulfills the requirements of the majority of automobile and light commercial vehicle manufacturers.